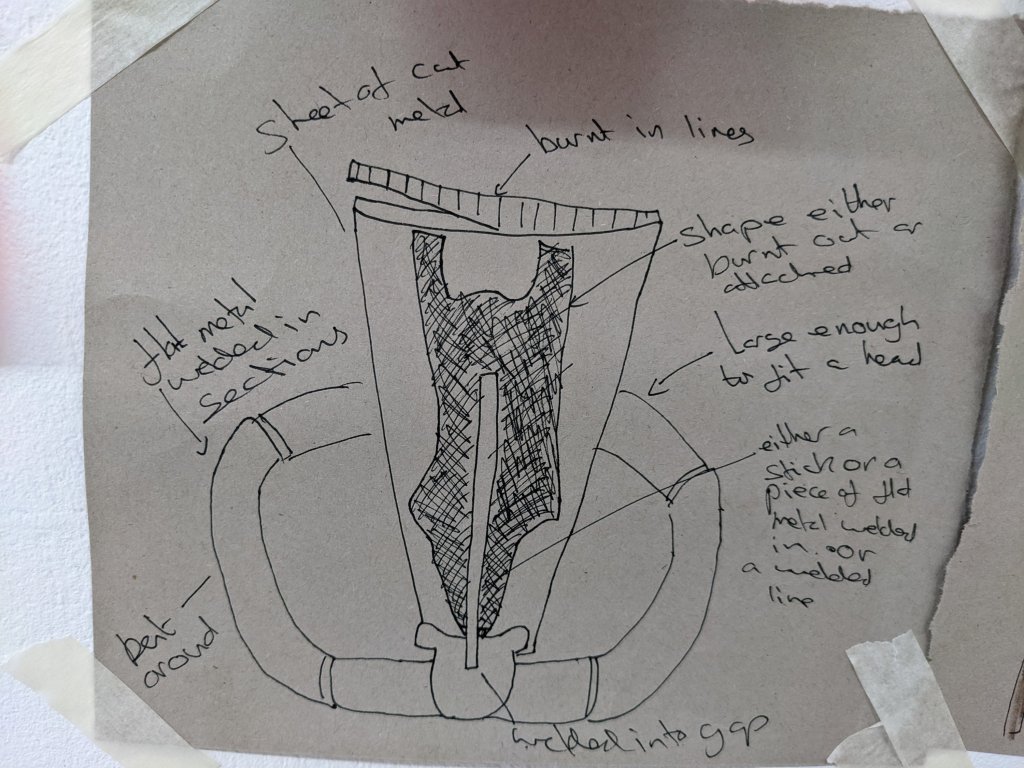

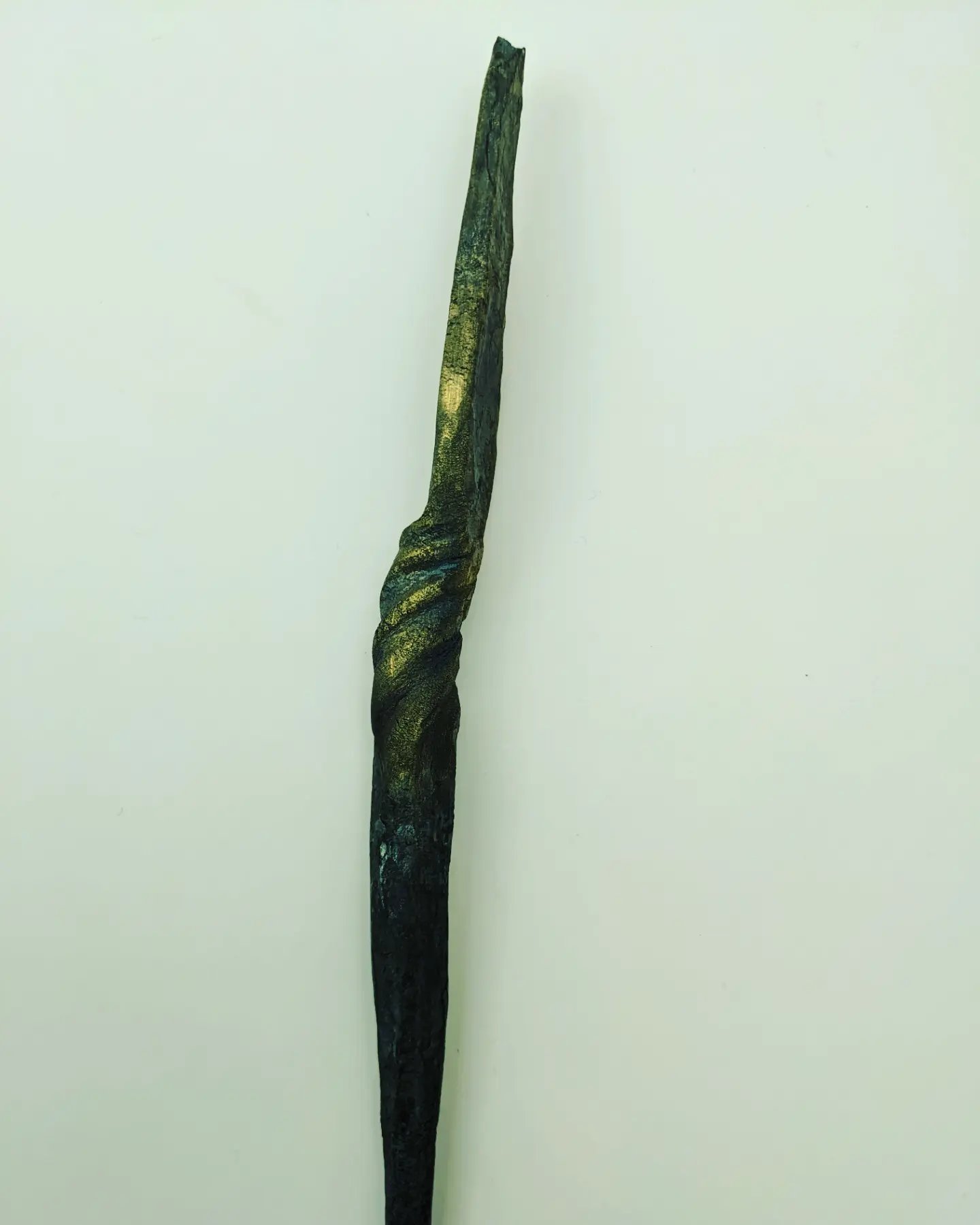

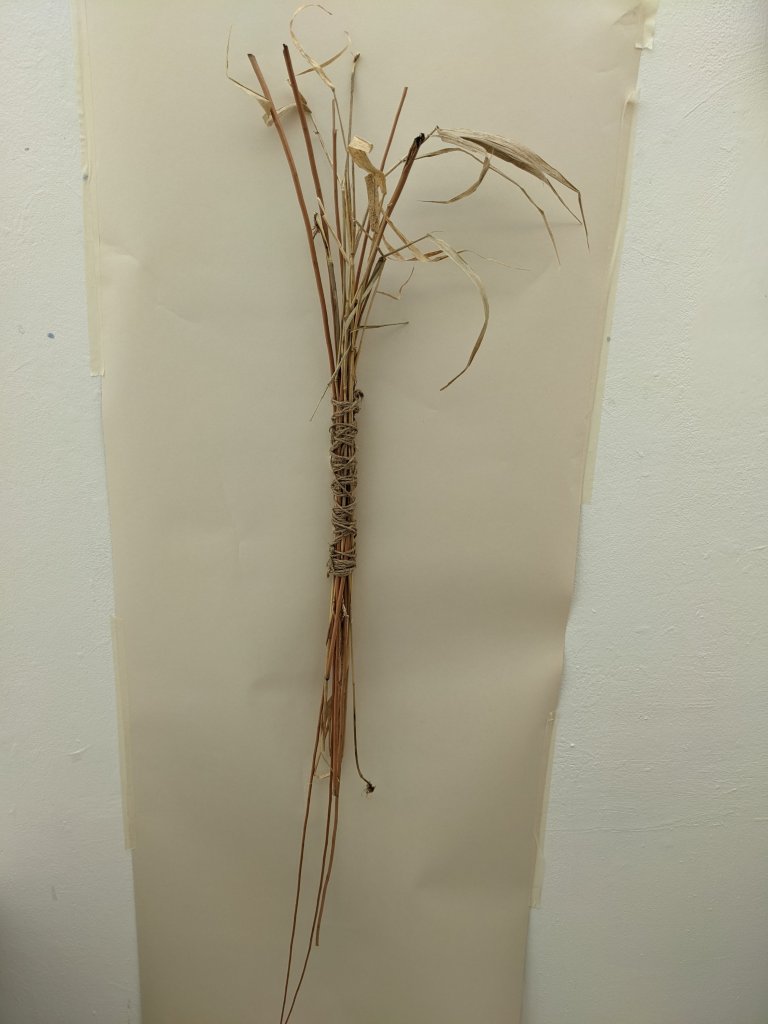

This week I was working between a mixture of disaplines (my favourite thing to do) I started off the week by learning another skill in forging which was to ‘draw out the metal’ in order to make a small spade like tool.I felt that it worked well with my theme and provided another ‘artifact’

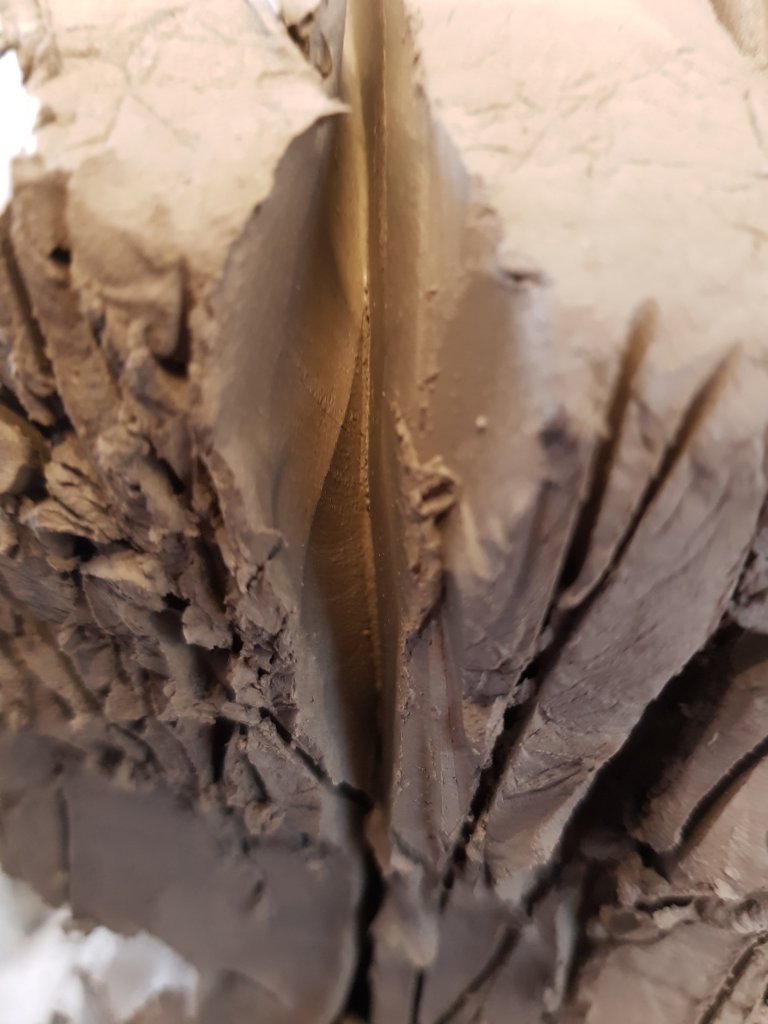

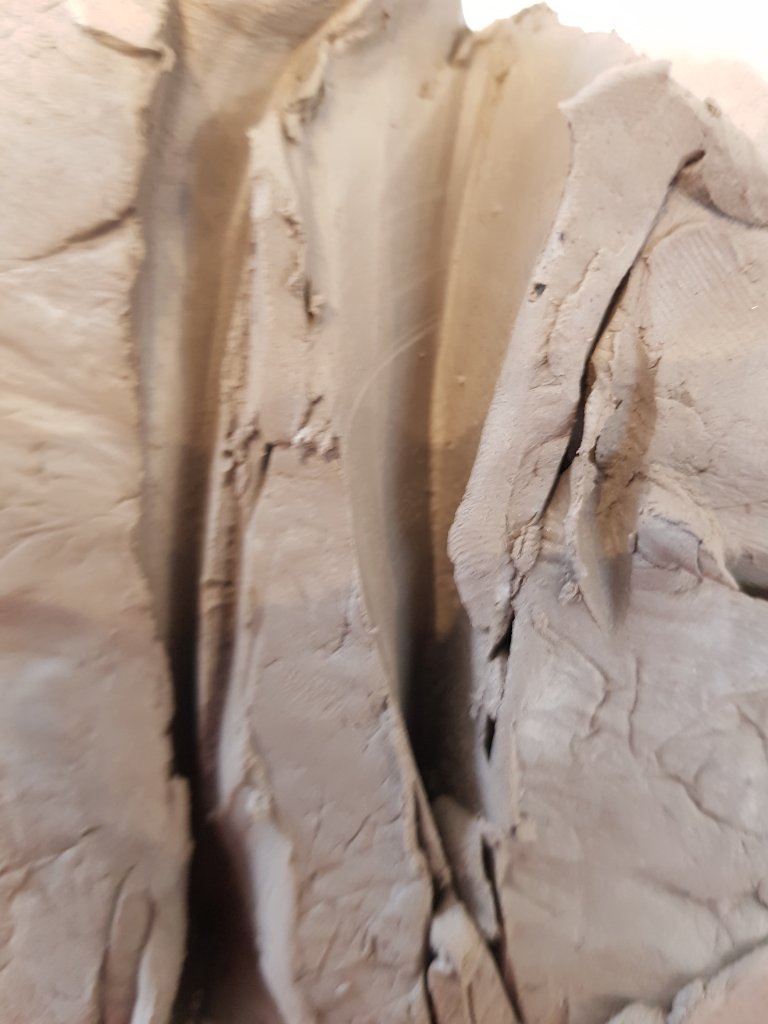

In order to make the flat end the metal had to be ‘drawn out’ by heating then hitting the metal from the top to the bottom of the heated section.The metal then had to be hit hard on the edge of the axel in order to create the ridge. The bottom half was also made by drawing out the metal and tapping the metal whilst rotating it on the axel and the twist (which is allways my favourite part) was made by simply heating the metal and twisting with a vice before brushing it over with a golden bristled brush for added effect.

For some reason my wrist and fingers were really hurting with the hitting that day.I blamed it on not using my favourite hammer but the technician told me this wasn’t true.I also prefer to use a lighter hammer as otherwise it puts too much strain on my wrist and I only have tiny wrists.The technician said that not everyone is built for forging and that if it hurts too much it’s ok to stop.But as they say ‘Mumma didn’t make no quitter’ haha

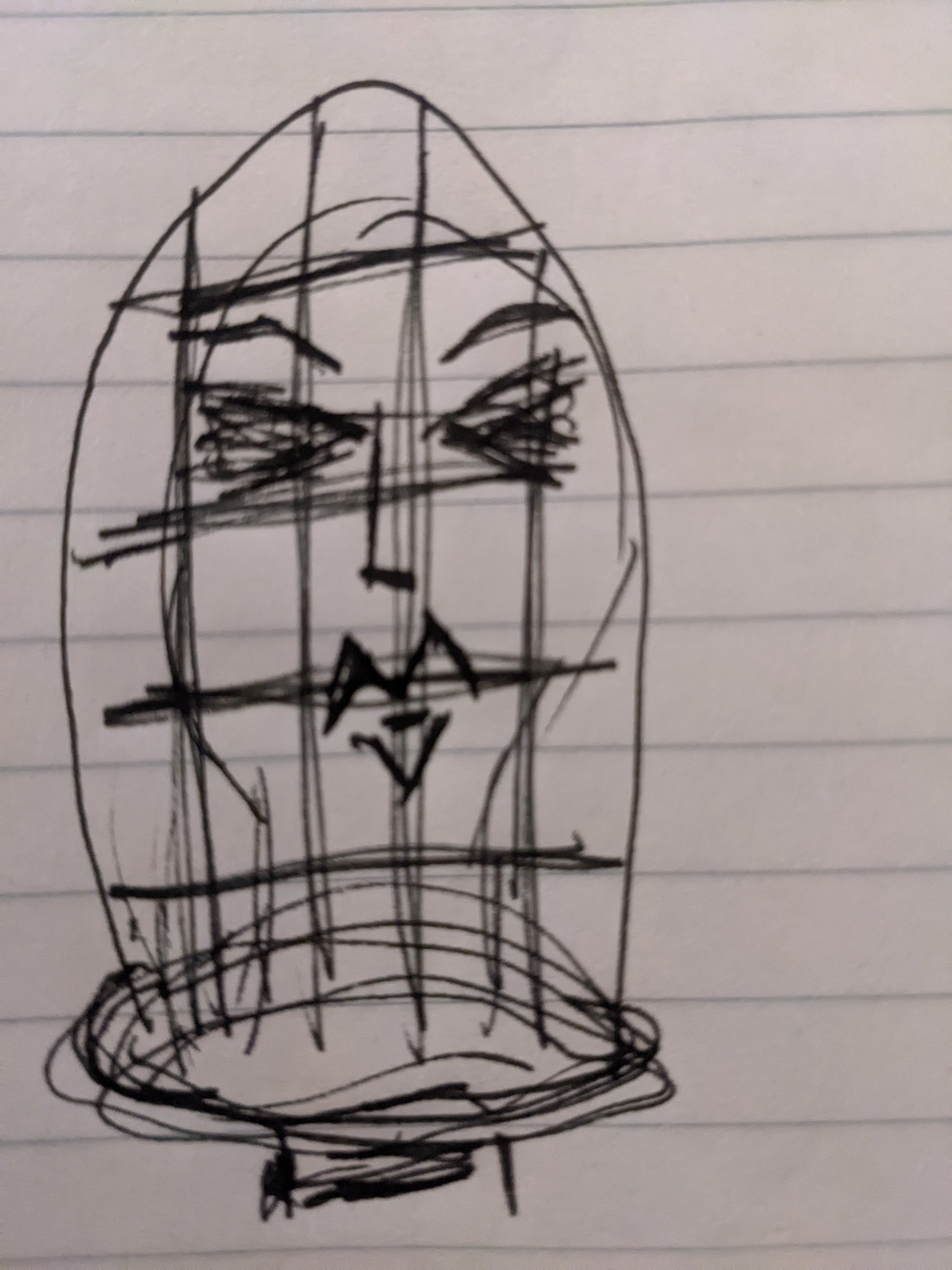

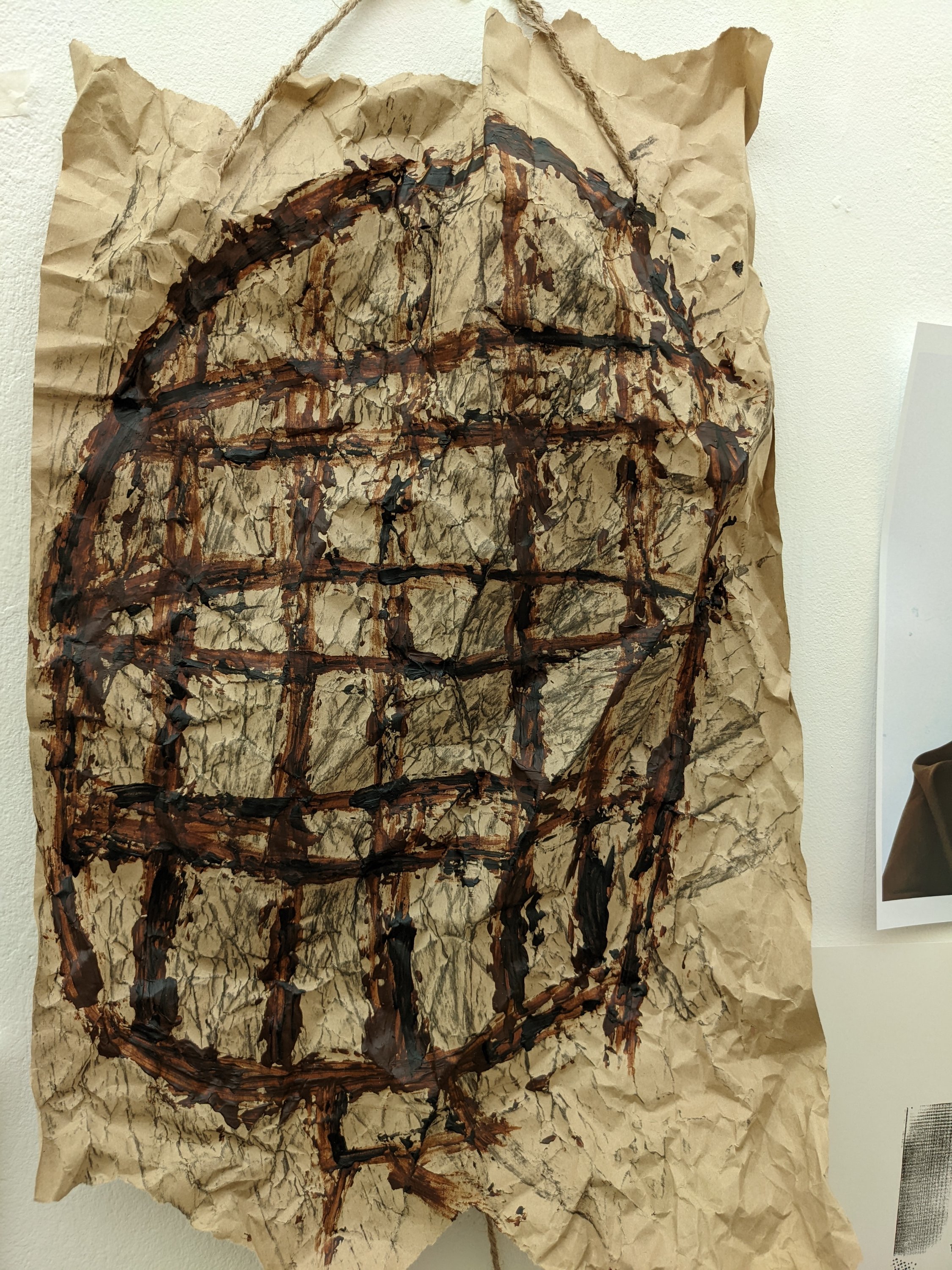

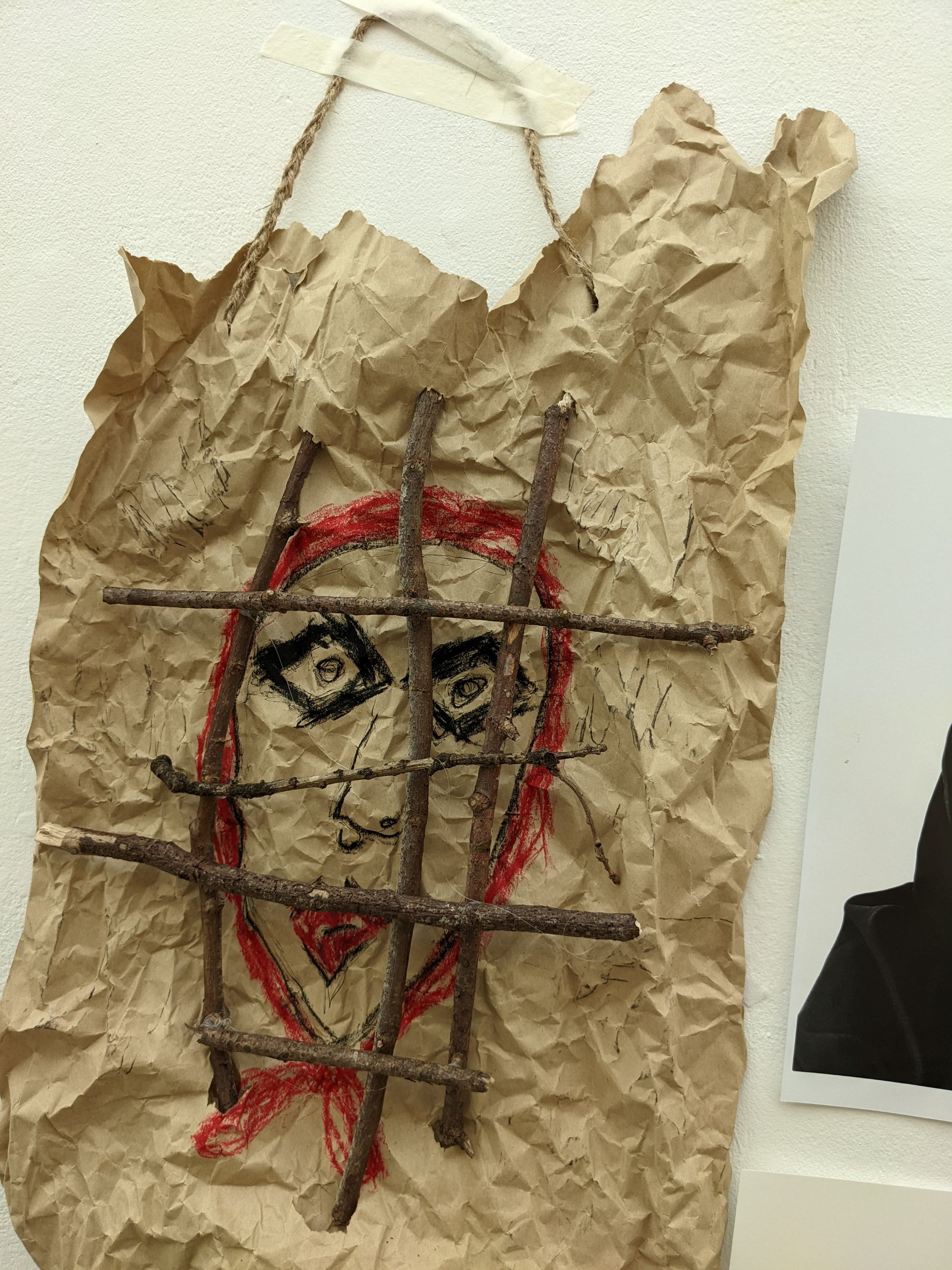

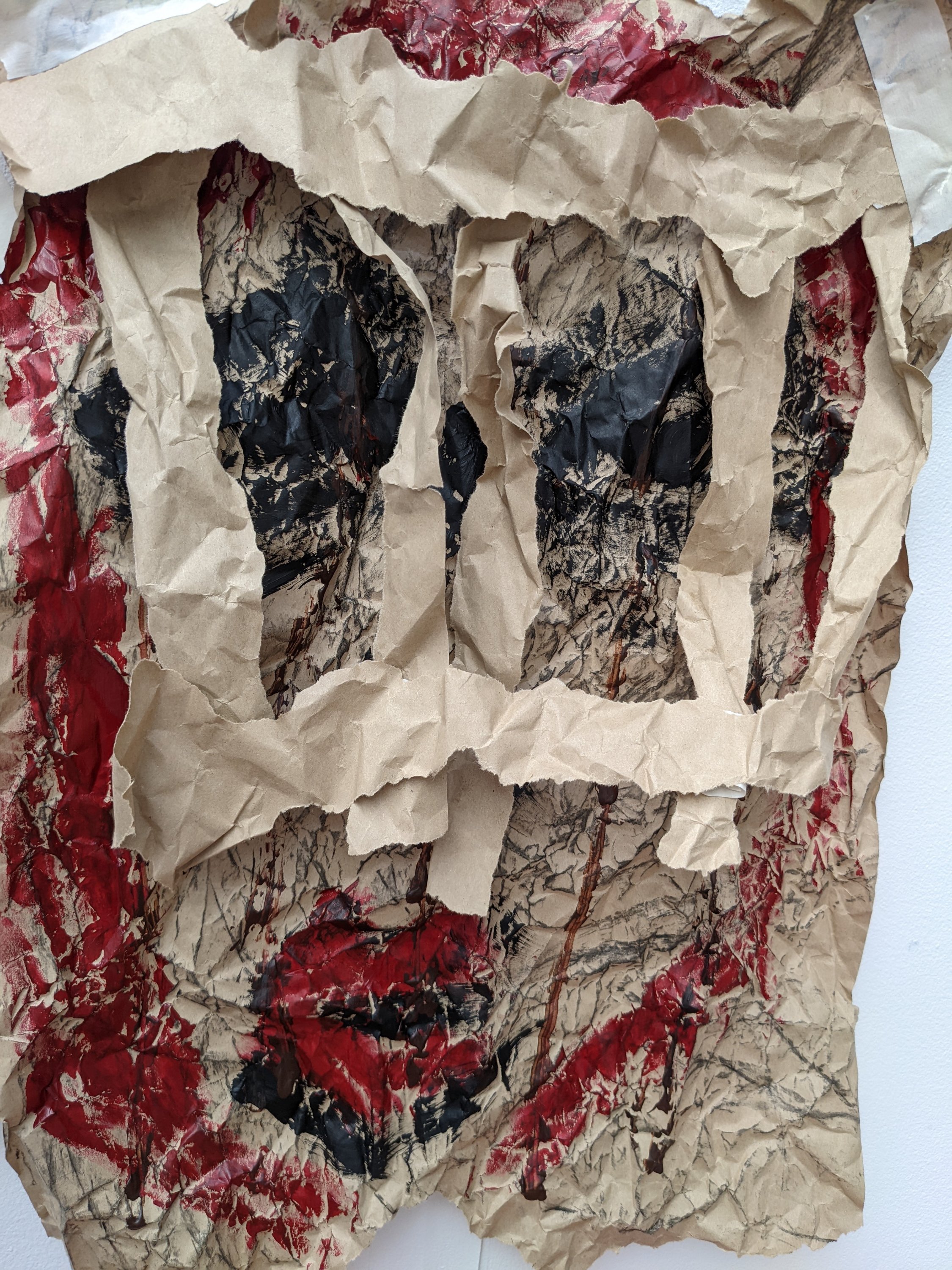

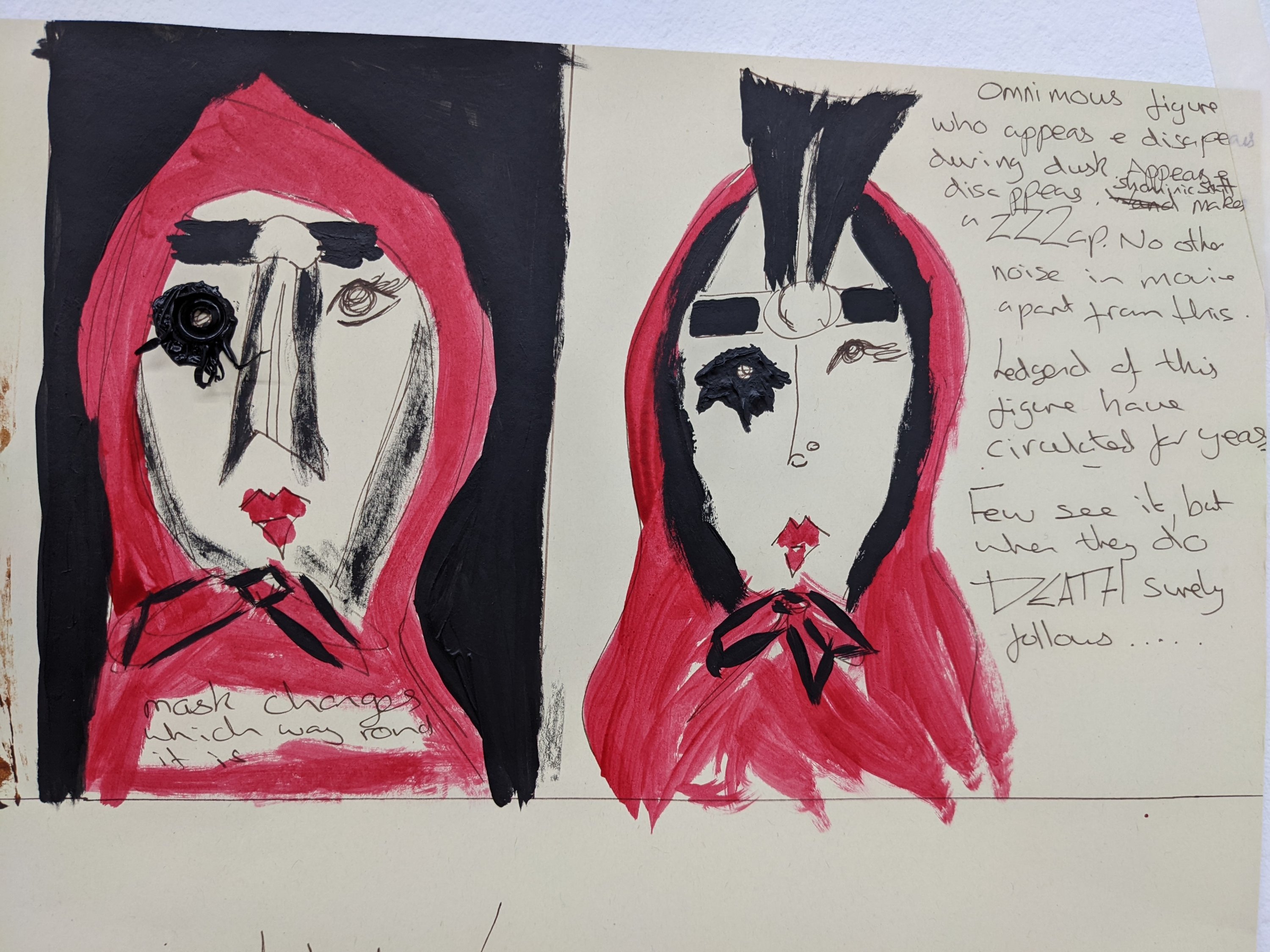

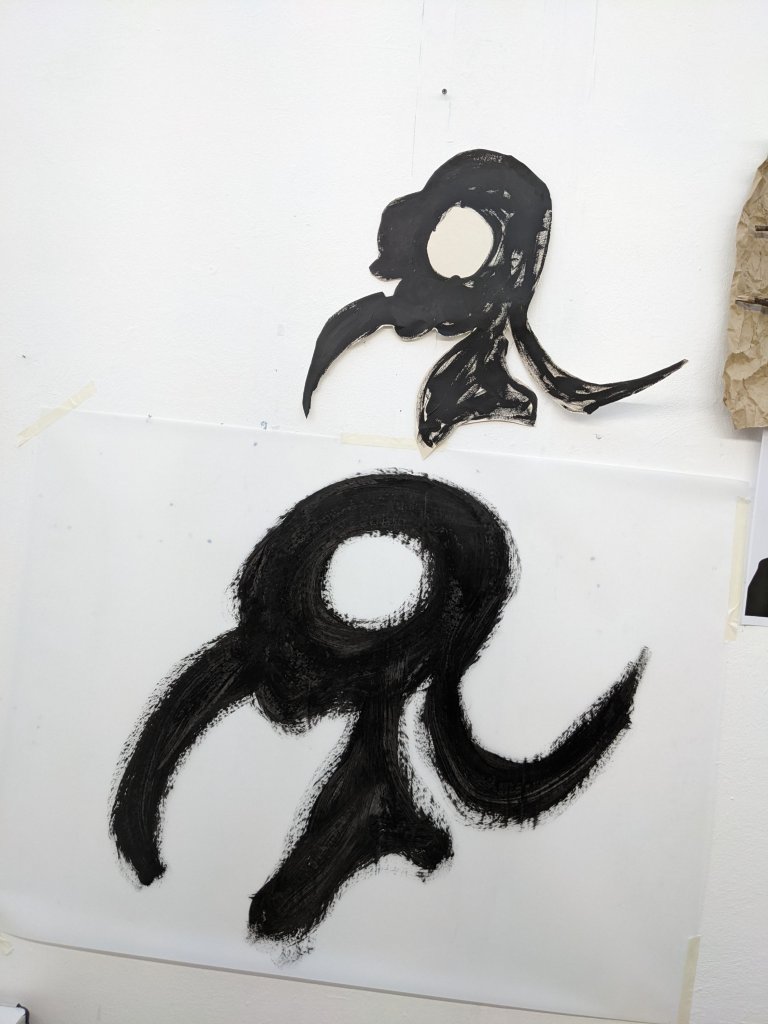

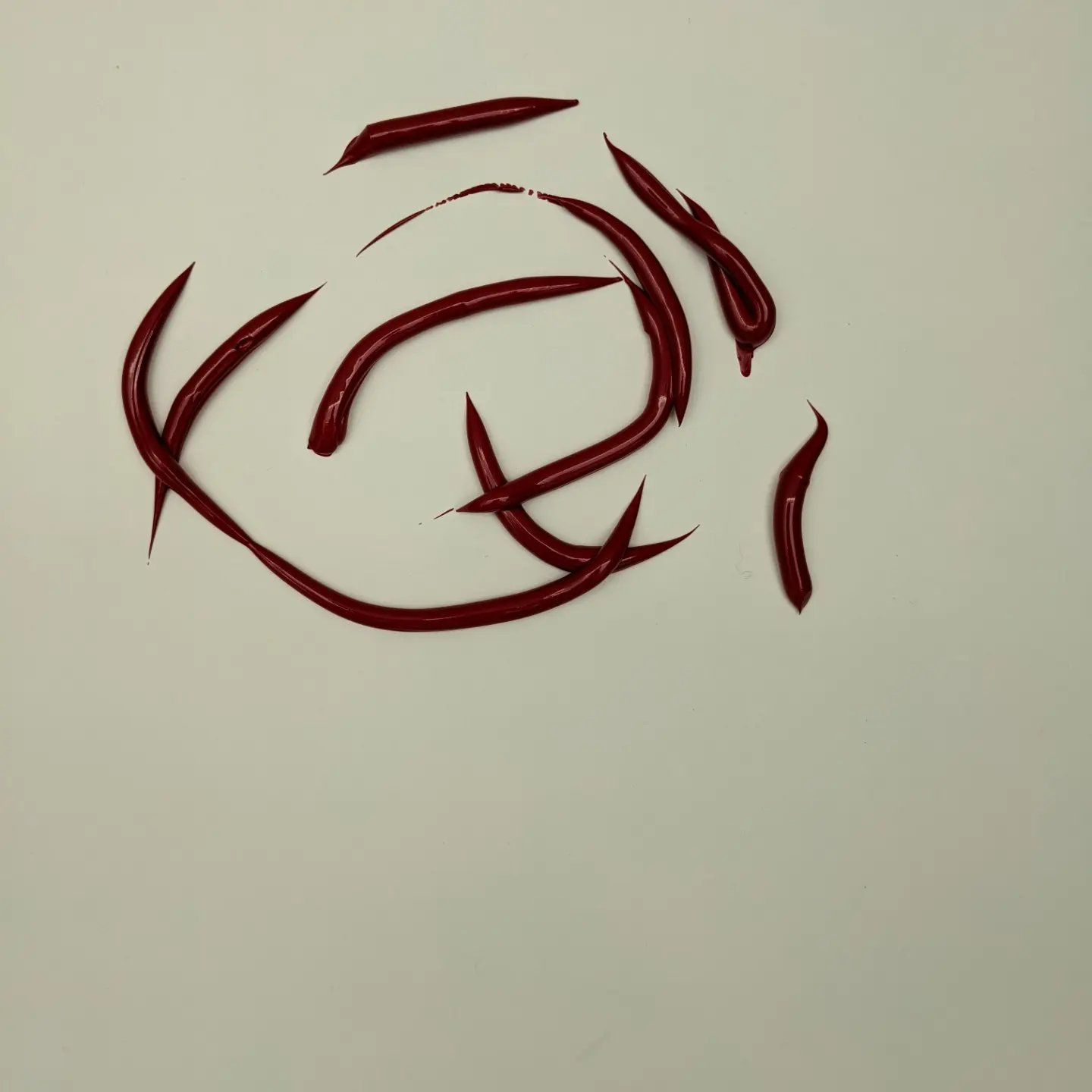

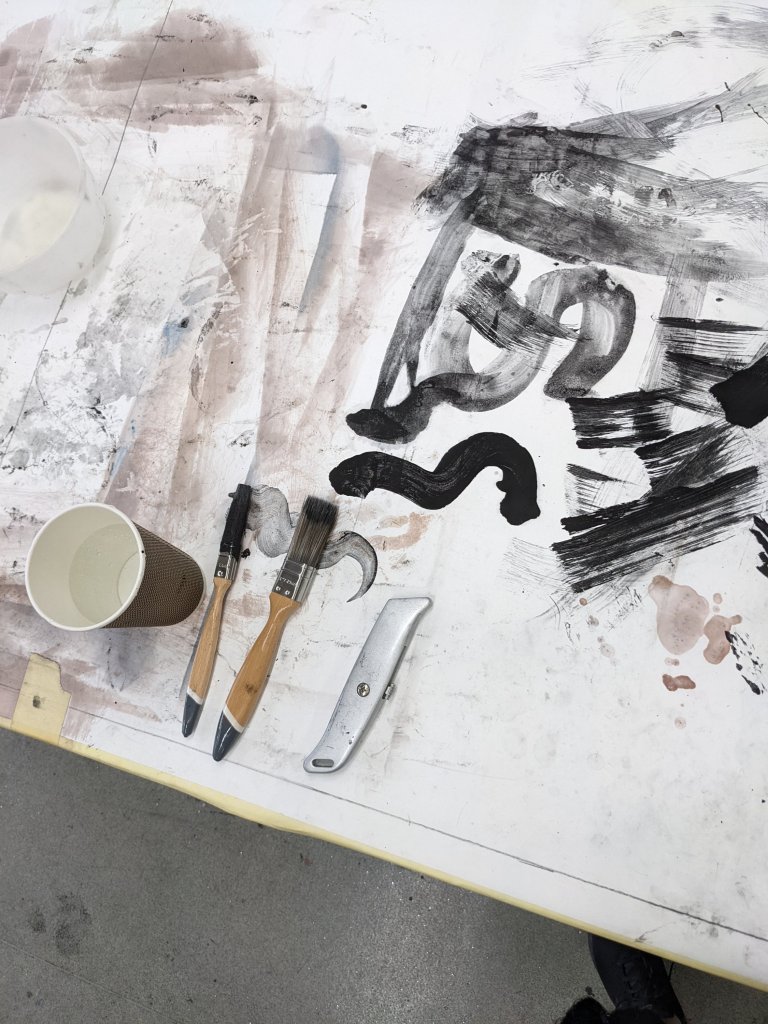

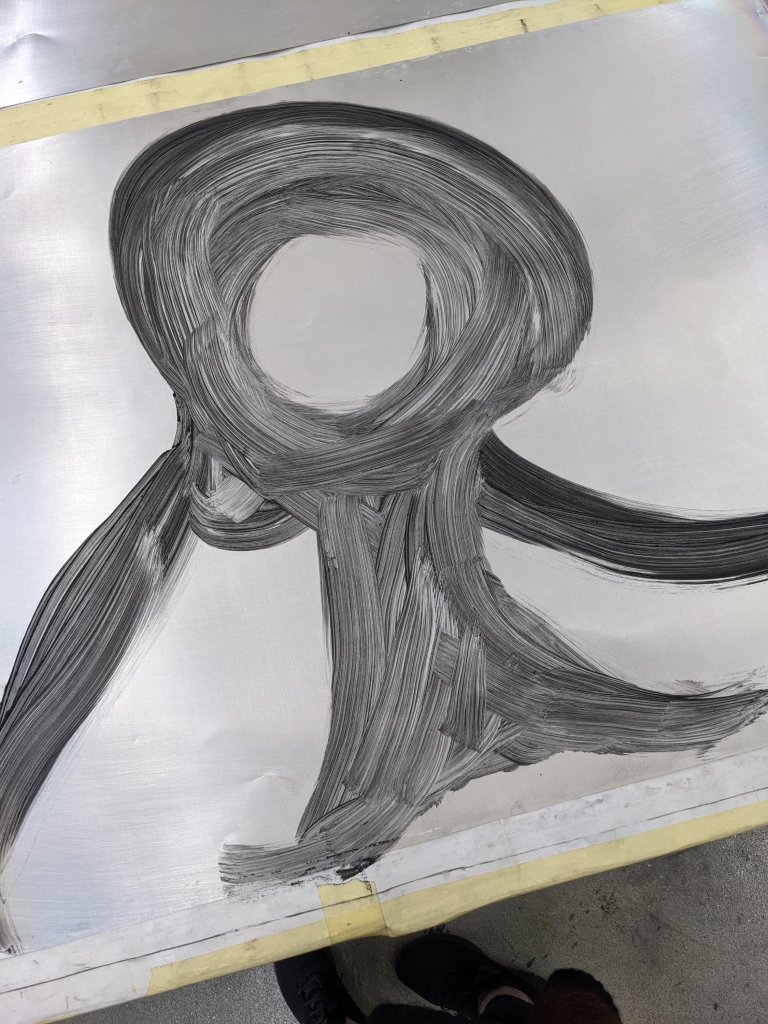

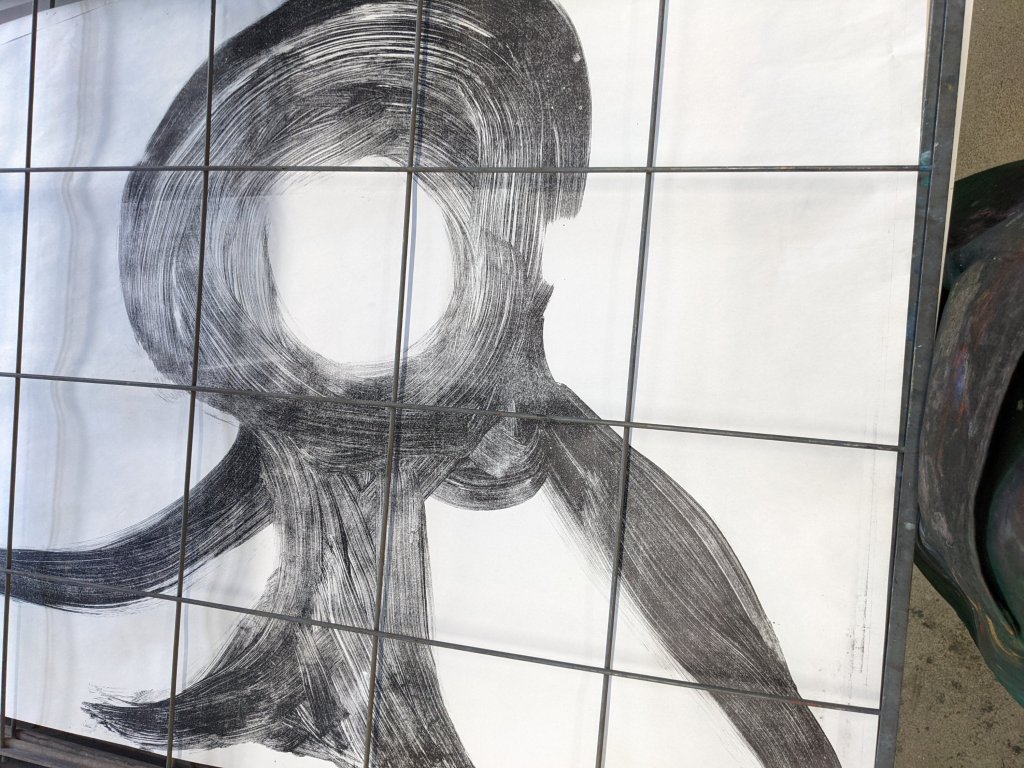

I decided to start the waterless lithography process for making a flag with the symbol on it. The process was deffinatley alot more then I expected and very meticulous.The process deffinately wasn’t as long as the foundry one tho.First the plates had to be cleaned with acetone,then scrubbed twice (with a liquid i think had silicon in it),rinsed and then a liquid applied which had a mixture of wheel cleaner and silicon in it before being dried off with newsprint before the design got painted on.I decided to use light washed down toner on one sheet and undiluted toner on another and a layer of silone with white spirits applied.The sheets then had to be left to dry over night before booking another session.I then had to use a heat gun on the design so that it would set into the aluminum sheet.To start with I didn’t have the heat gun close enough so the design hadn’t set and then i had it too close and the heat had travelled back up the gun causing smoke to billow out! (apparently this has never happened before) the gun had to be left at an open window to cool down!

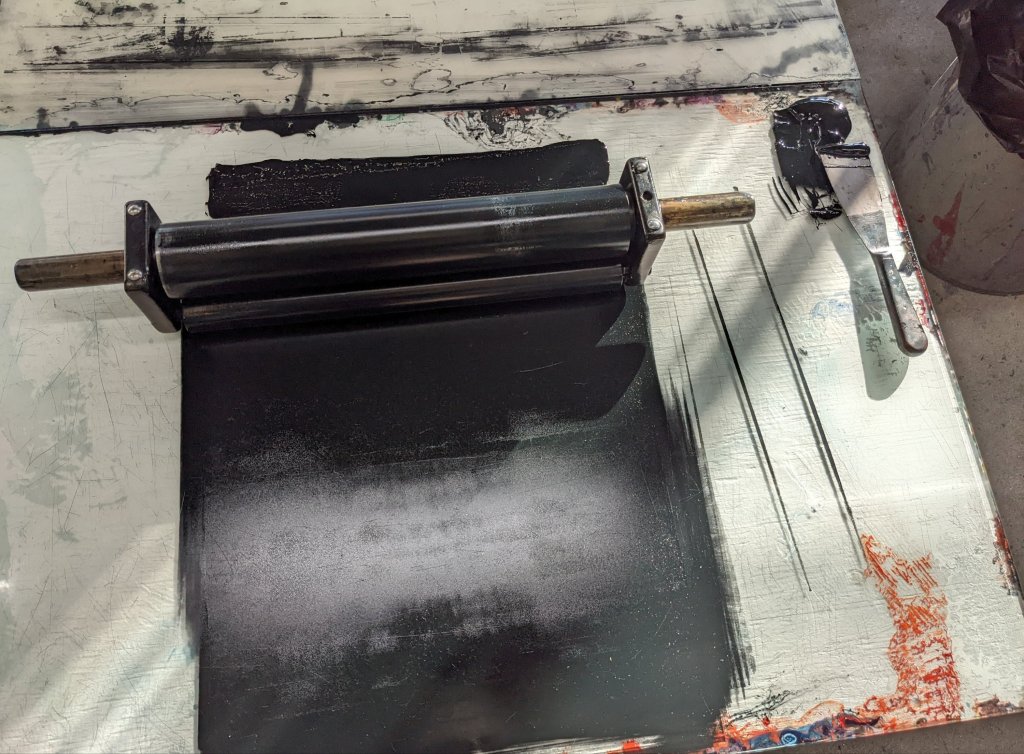

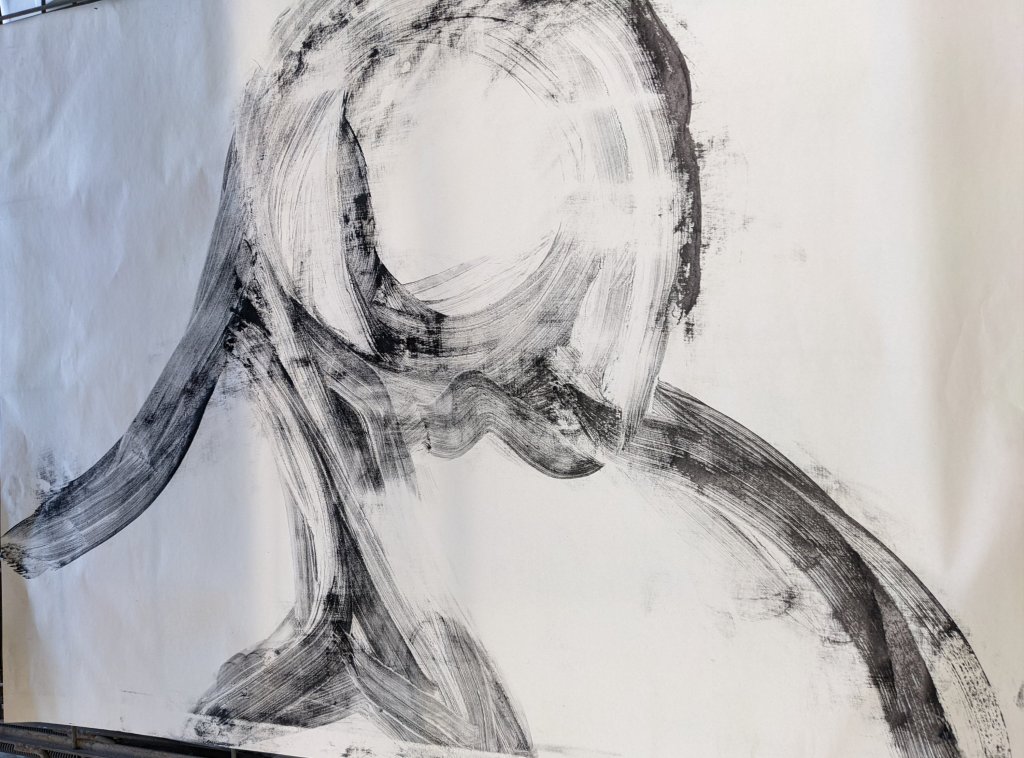

Once the ink was rolled up I then applied the ink by rolling it on I then put the design under the electric roller.It was interesting experimenting with more and less ink just to see how the final design would turn out.It was also hard sometimes to apply enough pressure so the ink would mark the plate showing up on the paper.I did lots of practice prints on newsprint.I was advised by the teacher to maybe go smaller on the design next time as it was too big for the paper and mounting board and would mark the sheet. There seemed to be a small part of the print missing on sheet i liked the most which may of been due to missing that section with the heatgun.The technician advised that waterless lithography would never be perfect and at some stage you just have to come to terms with what you have.But I find that really hard to do unless it is a ‘happy accident’ and i like the end result. Luckily as a back up I painted with acrylic onto some transfer paper the design but due to time limitations I have had to book another session next to do that in.

Next week I aim to try printing with the transfer paper and maybe try printing onto cloth and seeing how it goes.I can feel my impatience kicking in as I feel deperate to see the design as a flag allready but printing requires alot of patience which hopefully I will slowly learn that patience can pay off and results aren’t allways going to be instant but something that can slowly be worked on in time.

https://youtube.com/shorts/4wepq59k0GQ?feature=share

https://youtube.com/shorts/7L_Wvh19uDw?feature=share

https://youtube.com/shorts/Hvay6XEP3MM?feature=share

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_image/image/61078135/slender_man.0.jpeg)